The following ATEX protective measures are commonly implemented by our engineers to make sure your product complies to ATEX or IECEX regulations:

The following ATEX protective measures are commonly implemented by our engineers to make sure your product complies to ATEX or IECEX regulations:

- Flameproof (Ex d) – EN 60079-1

- Pressurisation (Ex p) – EN 60079-2

- Increased Safety (Ex e) – EN 60079-7

- Non sparking (Ex n) – EN 60079-15

- Intrinsic Safety (Ex i) – EN 60079-11

- Encapsulation (Ex m) – EN 60079-18

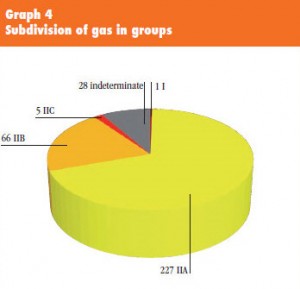

Equipment Group II is divided in gas groups and dust groups.

Gas Groups

Gas explosion protection is divided into 3 groups: IIA, IIB and IIC.

Picture 1

IIA: propane, butane, kerosene

IIB: ethylene, hydrogen sulphide, ethyl ether

IIC: hydrogen, acetylene, carbon disulphide

The subdivision of the gases in the Gas Groups is based on the Minimum Ignition Energy (MIE) with which an electrical spark can ignite the gas mix. Gases in Gas Group IIA require a higher ignition energy than Gas Group IIB. Gases in Gas Group IIC require the lowest ignition energy to ignite. As the table below shows, there are only 5 gases in Group IIC. Certifying your product for Gas Group IIA & IIB is usually sufficient to cover 98% of the market.

Electrical apparatus may be subdivided according to the nature of the potentially explosive atmosphere for which it is intended. The subdivision is based on the Maximum Experimental Safe Gap (MESG) for flame-proof enclosures or the Minimum Ignition Current (MIC) for intrinsically safe electrical apparatus as required in the specific European Standards

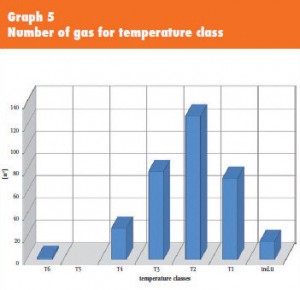

Temperature class

Picture 2

Every gas/air mix has its own specific ignition temperature.

This ignition temperature is defined as the minimum temperature at which the mix can be ignited. This can be the temperature of a hot object such as a chip on a PCB, a heating element, an electric motor or overheated mechanical bearings. To prevent ignition, the temperature must always be lower than the ignition temperature of the gas/air mixture.

Gas explosion-proof equipment is classified in temperature classes or “T classes”. Equipment that is classified in a certain temperature class can be used for gases with an ignition temperature that is higher than the temperature associated with the group.

Picture 2 shows the temperature class for common Gas Groups. Our aim is to certify your product for T4 temperature class, covering 99% of the market.

| Temperature class | Maximum permissible surface temperature |

|---|---|

| T1 | 450 °C |

| T2 | 300 °C |

| T3 | 200 °C |

| T4 | 135 °C |

| T5 | 100 °C |

| T6 | 85 °C |

Dust Groups

Dust protection is divided into 3 groups: IIIA, IIIB and IIIC.

The classification is characterised as follows:

| IIIA | combustible flyers (dust particles larger than 0.5 mm) |

| IIIB | dusts (dust particles smaller than 0.5 mm) |

| IIIC | conductive dusts (electrically conductive dust) |

| Temperature class | Maximum permissible |

|---|---|

| T1 | |

| T2 | |

| T3 | |

| T4 | 135 °C |

| T5 | 100 °C |

| T6 | 85 °C |